Aluminum Zinc and Magnesium Alloy Sacrificial Anode for Cathodic Protection

Overview Product Description Extruded Magnesium Alloy Sacrificial Anode AZ31B for Water Heater Product Description The m

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Transport Package | Wooden Case |

| Specification | AZ31 |

| Trademark | SINOMAGNESIUM |

| Origin | Zhengzhou China |

| HS Code | 8104902090 |

| Production Capacity | 100, 000 Piece Per Month |

Product Description

Product Description

Extruded Magnesium Alloy Sacrificial Anode AZ31B for Water Heater

Product Description

The magnesium alloy sacrificial anode (abbreviation: magnesium anode) developed and produced by our company according to the national standard GB/T17731-2009 "Magnesium alloy sacrificial anode" is suitable for the cathodic protection of metal structures in soil, fresh water and other media. As an ideal sacrificial anode material, this product has the following characteristics:

(1) The specific gravity is small and the potential is relatively negative.(2) The driving voltage to iron is high, and the current efficiency is low.(3) Large power generation per unit mass and long service life.

Product Type: | Magnesium Anode |

Material: | Magnesium alloy AZ31B |

Differnet kinds: | Casting rod,Extruded rod,Rod with steel cap,Flexible anode rod |

Chemical composition: | Al:2.5-3.5%, Zn:0.6-1.4%,Mn:0.2-1.0%,Fe:0.005%max,, Cu:0.01%max,Ni:0.001%max,Si:0.1%max, Other:0.3%max,Mg:Balance |

Propertices: | Open-circuit voltage: 1.5-1.55V Close-circuit voltage:1.45-1.50V Actual capacitance: 1.105A.h/g Current efficiency:50%min |

Steel cap: | stainless steel,galvannized ,in black,coppper,etc. |

Application: | It mainly used in water heater,boiler,heat exchanger,water tank,etc. It can softing water,de-dirt residual,ensure water sanitation,water scale inhibition,protect inner tank,extend service life,etc. |

Feasures: | The extruded anode rod can be with or without steel core,can be with steel cap or only with screw;the size of cap/screw can be customilized by your specific requirements. Mainly different kinds of steel cap and screw available. |

Product Parameters

Type: AZ31B, ZK61M, AZ80A, AZ91D, M2M, ME20M, AZ40

Specification: Casting round bar billet(Φ3-160*3000)

Remarks: According to the requirements of sawing and heat treatmentUK Standard ZK60 WE43 Magnesium Metal Plate Small Modulus Of Elasticity

Magnesium Alloy Chemical composition:

Semi-continuous casting products of high strength, heat resistant rare earth-magnesium alloy set by National Standard, ASTM, EN standard and autonomous development. The company can produce aylindrical bars with Dia. 90-800mm and casting slabs with max working size of 1200*450mm. the grain size of part of the alloys can be controlled under 90um, and the quantity of magnesium ingots has reached or exceeded correlative standards. The products have been widely used in major industries such as forging, extrusion, rolling etc.

| Alloy Element | Type | Chemical Composition% | Other elements b | ||||||||||||

| Mg | Al | Zn | Mn | Ce | Zr | Si | Fe | Ca | Cu | Ni | Be | Sub-total | total | ||

| MgAlZn | AZ31B | Balance | 2.5-3.5 | 0.6-1.4 | 0.1-0.2 | --- | --- | ≤0.08 | ≤0.003 | ≤0.04 | ≤0.01 | ≤0.001 | --- | ≤0.05 | ≤0.30 |

| AZ40M | Balance | 3.0-4.0 | 0.2-0.8 | 0.15-0.5 | --- | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.005 | ≤0.01 | ≤0.01 | ≤0.30 | |

| AZ80A | Balance | 7.8-9.2 | 0.2-0.8 | 0.12-0.5 | --- | --- | ≤0.10 | ≤0.005 | --- | ≤0.05 | ≤0.005 | --- | --- | ≤0.30 | |

| AZ91D | Balance | 8.5-9.5 | 0.45-0.9 | 0.17-0.4 | --- | --- | ≤0.08 | ≤0.004 | --- | ≤0.025 | ≤0.001 | 0.0005- | ≤0.01 | ≤0.30 | |

| 0.003 | |||||||||||||||

| MgMn | M2M | Balance | ≤0.20 | ≤0.30 | 1.3-2.5 | --- | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.007 | ≤0.01 | ≤0.01 | ≤0.20 |

| MgZnZr | ZK61M | Balance | ≤0.05 | 5.0-6.0 | ≤0.10 | --- | 0.3-0.9 | ≤0.05 | ≤0.05 | --- | ≤0.05 | ≤0.005 | ≤0.01 | ≤0.01 | ≤0.30 |

| MgMnRe | ME20M | Balance | ≤0.20 | ≤0.30 | 1.32-2.2 | 0.15-0.35 | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.007 | ≤0.01 | ≤0.01 | ≤0.30 |

Our Advantages

- Corrosion protection

- Protect water heater, water containers of steel structure

- Protect the gas pipeline in-home service polarization high resistance electrolytes (soil and water in the steel structure)

Aplication

1. TransportationSeat frame, armrest, small table panel, pedal, in-built profiles, driving frame, sleeper frame work, dashboard frame work etc.2. ElectronicsMagnesium alloys have excellent thin wall casting performance. They wall thickness of magnesium alloy die castings can reach 0.6-1.0mm, and the die castings can remain certain strength, stiffness and impact resistance. These performances are very consistent with development demand of lightweight, thin short and small for laptop. Mobile phone, digital camera, that makes the application of magnesium alloy grow sustainably.3. Aerospace industryEngine shell, parts. Skin and cabin, frame, holder, wingtip, aileron, fuel tank, gearbox, airscrew, seat, undercarriage, all kinds of shell, siding, clapboard etc.4. Military industryPanzer tank vehicle, torpedo, guided missile, aircraft / spacecraft, military electronic equipment, military statellite.5. Medical industryMedical device and implant material.

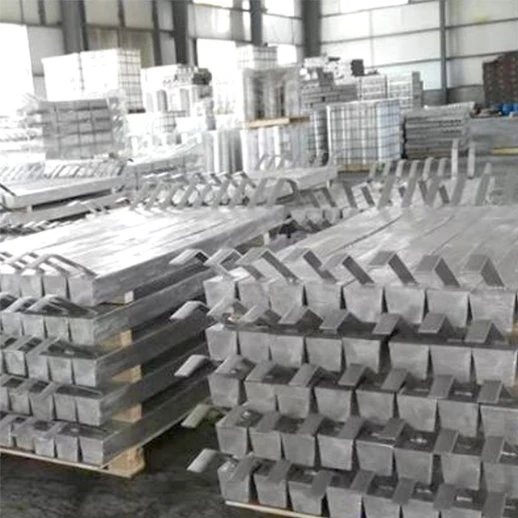

Detailed Photos

Workshop

Packaging & Shipping

FAQ

Q: Do you provide OEM/ODM service?

A: Yes, OEM/ODM is welcome, we have the professional R&D team.

They work for you all the time (design, tooling/mould, sample, mass production).

Q: How can I know your company further?

A: Please leave message in website with you email or phone number, the sales manager will send the catalogue to you by email or call you directly.

Also welcome to visit our company!

Q: How can I get the quotation, sample, mass production?

A: Please show us the sizes/drawing of the parts you need, our business director will show you detailed quotation with the lead time of sample and mass production.

Q: How do you control the quality?

A: The products are produced under ISO9001 & SGS certificate.

The documents of PPAPIII, FAI, inspection Report also will be sent to you for Checking if needed.

Company Profile

Sino Zheng Industrial Inc. is one of a leading & professional suppliers of forging magnesium wheel, magnesium welding wire, magnesium rod as well as magnesium alloy profiles in Zhengzhou China. Our company uses advanced production technology and automation equipment to ensure the high quality and high stability of magnesium alloys. Our magnesium alloy rods are refined by a special process, with small grains, uniform inside and outside, low impurity content, and no peeling; the company's die-casting production line uses these magnesium alloy rods as raw materials to produce magnesium alloy bicycle frames, rims, and magnesium alloys. High-quality products such as crossbow racks.

Our company has now developed a formula and process for producing high-quality magnesium alloys, which are inimitable. Magnesium alloy welding wire produced with this formula and process can realize compatible welding between different magnesium alloy materials, that is, different materials of magnesium alloy can be welded with one kind of welding wire, and have the advantages of small thermal effect zone, deep welding penetration, and no blistering. In particular, the 1.2mm magnesium alloy welding wire produced uses a one-time extrusion process to replace the original extrusion and then drawing process. Relying on the excellent technical team in the industry, the company continuously expands the application range of magnesium alloy materials through technological innovation, product innovation and process innovation, and contributes to the development of my country's magnesium alloy industry.

Our company is currently a professional manufacturer of magnesium alloy welding wire in China. The magnesium alloy welding wire produced by the company has specifications such as 1.2mm, 2.4mm, 3.2mm, etc., all of which are produced by one-time extrusion molding process with stable quality. With these magnesium alloy welding wires, different types of magnesium alloys can be welded together. The heat effect zone of the welded parts is small and the weld strength is higher than the non-welded zone. The bicycle frames welded with these magnesium alloy welding wires can achieve more than 150,000 vibration tests without cracks.

The application of magnesium alloy welding wire completely solves welding problem of magnesium alloys, can promote the wide application of magnesium alloys in military, aerospace, and civil applications, can increase the total application of magnesium alloys in the country, and maximize the high reserves of magnesium alloys in the country propelling the magnesium industry into a stage of rapid development will bring a material revolution to our country.